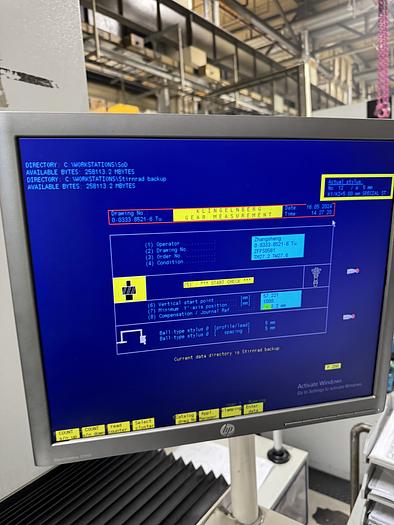

Fully Automatic CNC-Controlled Gear Measuring Center KLINGELNBERG P 200

Fully Automatic CNC-Controlled Gear Measuring Center KLINGELNBERG P 200

€220,000 (EUR)

Location:Sankt Leon-Rot, Germany

or

Call +4917663478044

Description

Fully Automatic CNC-Controlled Precision Measuring Center P 200

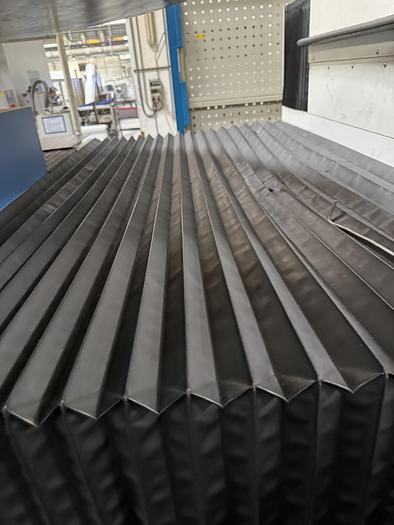

The Precision Measuring Center P 200 is designed for workpieces with a diameter of up to 2,000 mm and is used for inspecting various types of spur gears, large bevel gears, and worm gears.

Key Features:

- Fast and precise data acquisition in combination with a high-precision workpiece rotary table.

- Multiple measurement tasks in a single clamping, suitable for coordinate, form, gear, and roughness measurements.

- Versatile scanning 3D probe system with digital data acquisition in all coordinate directions.

- High fundamental accuracy with low tolerances.

- Easy graphical programming environment and user-friendly software interface.

- Significant time savings due to quick availability of measurement results.

General Data

- Module (min. – max.): 1 – 85 mm

- Horizontal measuring range (X-axis): ±300 mm

- Permissible workpiece weight: approx. 20,000 kg *12

- Vertical measuring range (Z-axis): 1,200 (1,500, 2,000) mm

- Machine accuracy for gear measurement according to VDI/VDE 2612 Sheet 6: Group A

- Helix or lead angle (min. – max.): 0° – 90°

- Workpiece mounting diameter on rotary table (min. – max.): 220 – 1,000 mm

- VDI2631 Radial guideway deviation: 0.5 µm

Measurement Accuracy under Compliance with the Reference Temperature +18 °C – 22 °C

- Reference temperature: 0.5 K/h; 2 K/day; 0.7 K/m

- MPEE0 ISO 10360-2 (2010): 2.2 µm + L /250mm

- Roundness Ø 100/L VDI/VDE2617-Sheet 8: 0.6 µm

- Total run-out VDI/VDE2617-Sheet 8: 1.8

General Machine Data

- Total power requirement: approx. 6.5 kVA

- Compressed air connection: 6 bar / 120 l/h

- Net weight incl. standard accessories: approx. 19,000 kg

Specifications

| Manufacturer | KLINGELNBERG |

| Model | P 200 |

| Year | 2010 |

| Condition | Used |

| Stock Number | 6775 |