Mazak Quick Turn Nexus 200-II MY CNC

Mazak Quick Turn Nexus 200-II MY CNC

€40,000 (EUR)

Location:Sankt Leon-Rot, Germany

or

Call +4917663478044

Description

Properties

Chuck diameter main spindle 8 "

Max swing diameter 675 mm

Standard machining diameter 276 mm

Max machining diameter 380 mm

Max bar diameter main spindle 65 mm

Distance between spindle end and turret 135 mm - 710 mm

Max workpiece weight chuck machining main spindle 300 kg

Max workpiece weight shaft machining main spindle 700 kg

Main Spindle

Max speed 5000 min-1

Min speed 35 min-1

Spindle nose A2-6

Acceleration deceleration 22 msec

Spindle bore 76 mm

Motor power 30 min operation 260 kW

Max torque 4650 Nm

Tailstock

Mounting MK 5 fixed center

Travel range tailstock body 550 mm

Max thrust force 700 kgf

Turret

Number of tools 12 driven tools usable in all stations

Tool cross-section external turning tool 25 mm²

Boring bar diameter max 40 mm

Tool size drill 20 mm

Tool size milling cutter 20 mm

Tool size tap M20 x 25

Indexing time 1 turret station 020 sec

Indexing time full turret rotation 060 sec

Milling spindle power 10 min operation 55 kW

Max milling spindle speed 4500 min-1

Min milling spindle speed 25 min-1

Max torque milling spindle 353 Nm

Feedrates

Rapid traverse X-axis 300 m min

Rapid traverse Y-axis 210 m min

Rapid traverse Z-axis 330 m min

Rapid traverse C-axis 555 min-1

Max constant feedrate X-axis 85 msec

Max constant feedrate Y-axis 85 msec

Max constant feedrate Z-axis 90 msec

Travel range X-axis 230 mm

Travel range Y-axis 100 mm

Travel range Z-axis 575 mm

Others

Tank capacity 190 L

Power consumption 30 min operation 474 kVA

Power consumption continuous operation 416 kVA

Air pressure 50 bar

Required air volume 150 l min

Machine Dimensions

Center height 1020 mm

Length 2665 mm

Width 1860 mm

Height 1860 mm

Weight 5100 kg

STANDARD ACCESSORIES

GENERAL MACHINE OPTIONS

Transformer for the European market

Set of manuals in electronic format on CD

1 set of alignment tools

Foundation set plates

Support plates for the machine’s leveling feet If the machine is anchored these plates must be drilled by the customer

Mazak standard color

Spindle orientation in a fixed position

C-axis input accuracy 00001°

Main spindle motor AC 26kW

Spindle speed 5000 min-1

Tool turret with 12 stations

Spindle speed for driven tools 4500 min-1

NC programmable tailstock

The tailstock has its own servo drive selection of movement direction is done via M-code in the program

Tailstock with fixed center MT No5

Tailstock thrust force adjustment in 9 steps

Each step can be selected in the program via an M-code

Rotating tailstock center type NSK LC-5SW 5000min-1 MT No5

Y-axis control

SAFETY FEATURES

Operator door with interlock switch

Dual foot switch

Opening and closing of the chuck through separate switches

Hydraulic pressure interlock

Monitoring of the machine’s hydraulic pressure If pressure drops the machine stops and an alarm is triggered

Fully enclosed work area

Protection from chips coolant and access to the work area during automatic machining

Work area lighting

Safety measures according to global standards

COOLANT SYSTEM

High-performance coolant system 520W max flow rate 115 l min

Complete coolant system including pumps valves piping and nozzles for efficient machining of high-quality parts

CHUCK SYSTEM ETC

Chuck status monitoring

Feedback of chuck status via sensors

8 chuck with through-hole main spindle chuck Kitagawa BB208 with bar passage 65 mm

MEASUREMENT SYSTEM

Automatic tool eye

Measurement of tools in the machine during setup mode or for tool wear compensation and tool breakage detection in automatic mode

CHIP DISPOSAL

Preparation for chip conveyor side-mounted

ADDITIONAL FUNCTIONS

Hand grease gun LG-400 required

Grease cartridge EP-1

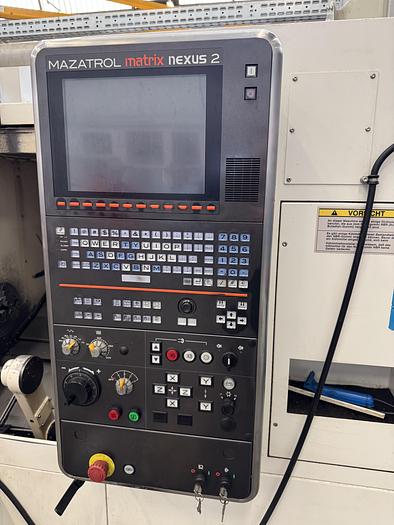

NUMERICAL CONTROL

Synchronized threading with milling spindle

Fast and high-precision threading by synchronizing the milling spindle with the feed axis

Relocation detector

Mazatrol Matrix Nexus 2

12 1" LCD color screen

User macro 600 variables

Mazak threading drilling cycle Tornado in EIA ISO Only on machines with Y-axis possible With this function screw-threaded drilling or boreholes including chamfering of different sizes can be produced with just one tool

EIA ISO input function

Optional stop

Automatic operation is stopped when code M01 is programmed the menu for optional stop remains displayed

Tool path verification in background

The tool path of a program can be checked even if another program number is called up and executed in automatic mode

Thread cutting function G33

Ball interpolation moving EIA

Results in movement that can be specified with radius and angle

Specifications

| Manufacturer | MAZAK |

| Model | Quick Turn Nexus 200-II MY |

| Year | 2014 |

| Condition | Used |

| Stock Number | 6777 |